|

|

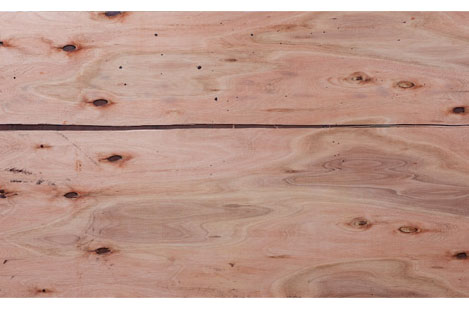

CCX/CDX Structural Plywood CCX/CDX Structural Plywood

CCX and CDX is a sustainable plywood product derived from pine and eucalyptus trees grown and cultivated in Uruguay according to well-managed forestry practices and offers excellent performance, aesthetic, and environmental benefits. CCX and CDX is a sustainable plywood product derived from pine and eucalyptus trees grown and cultivated in Uruguay according to well-managed forestry practices and offers excellent performance, aesthetic, and environmental benefits.

Competitively priced CCX/CDX panels boast top certifications, including PS 1-07 and CE 2+ EN636 certification and technical documentation. CCX/CDX panels boast top certifications, including PS 1-07 and CE 2+ EN636 certification and technical documentation.

These high-qualities, sustainable panels are designed for construction and industrial use such as packaging, shelves, partitions and decking etc.

Structural Panels are truly WBP (Exterior) light density high performance panels bonded with low emitting formaldehyde resin. The panels are made with machine composed core to guarantee the best performance value. To ensure, dimensional stability of the panel, the central ply consists of two face to face laminated veneers in case of even plies constructed Plywood. Structural Panels are truly WBP (Exterior) light density high performance panels bonded with low emitting formaldehyde resin. The panels are made with machine composed core to guarantee the best performance value. To ensure, dimensional stability of the panel, the central ply consists of two face to face laminated veneers in case of even plies constructed Plywood.

This unique technology provides the dimensional stability in the rigorous conditions involving wide changes in the atmospheric humidity.

Key Benefits Key Benefits

- Highly wear resistant

- Resistant to most aggressive environments, including chemicals

- Higher water resistance, boiling waterproof

- Hard surface, durable and stable

- Fresh indoor air quality, free from toxic VOCs

- Resistance to temperature variation: through a range of -40°C to +50°C (-40°F to +122°F), comes in a variety of thicknesses and sizes

What does our promise of Efficiency mean to you

- Products that improve your cost, material and energy efficiency

- Reliable and timely deliveries

- Local knowledge, support and service

- Solutions for every application

- Proven and documented technical data and environmental statements

Certifications Certifications

- Certified products are also available under the chain of custody programs on prior arrangement.

Mean Test Values - Imperial Units

| |

Unit |

CCX/CDX |

| Composition |

|

All - Eucalyptus |

Pine/Eucalyptus |

| Thickness |

|

15mm |

18mm |

15mm |

18mm |

| References |

|

TECO 09-P-0026 |

TECO 08-P-0127Weyco WSE09-004 |

TECO 09-C-0027 |

TECO 06-P-0180Weyco 09-004 |

| Span Rating |

in/in |

40/20(3) |

48/24(3) |

40/20(3) |

48/24(3) |

| Group Rating |

|

|

|

Group 1(3) |

|

| Average Weight |

Kg |

23.3(3) |

27.7(3) |

24.6(3) |

29.2(3) |

| Density (6%MC) |

Kg/m3 |

503(3) |

503(3) |

537(3) |

533(3) |

| MOEP - Parallel |

N/mm2 |

8,110(3) |

8,730(3) |

8,130(3) |

8,260(3) |

| MOEP - Perpendicular |

N/mm2 |

2,590(3) |

2,460(3) |

2,700(3) |

3,160(3) |

| MORP - Parallel |

N/mm2 |

31.3(3) |

32.0(3) |

29.2(3) |

31.2(3) |

| MORP- Perpendicular |

N/mm2 |

16.8(3) |

15.1(3) |

25.6(3) |

22.6(3) |

| Maximum Shrinkage - Parallel |

Percent |

|

0.21 |

|

0.33 |

| Maximum Shrinkage - Perpendicular |

Percent |

|

0.28 |

|

0.30 |

| Screw Withdrawal(1) - Face |

N |

|

1330 |

|

1670 |

| Screw Withdrawal(1) - End |

N |

|

1100 |

|

1290 |

| Screw Withdrawal(1) - Edge |

N |

|

1005 |

|

1250 |

| Staple Withdrawal(2) - Face |

N |

|

961 |

|

1090 |

| Staple Withdrawal(2) - End |

N |

|

992 |

|

1240 |

| Staple Withdrawal(2) - Edge |

N |

|

1290 |

|

1150 |

Properties Properties

- Waterproof,

- Strong and light

- Meets EUTR standards,

- Meets European E1 formaldehyde emission requirements (EN 120:1992) and also California ARB regulation P2

Veneers Veneers

- 100% natural whole piece or spliced Eucalyptus or Pine Veneers of 3mm and/or 3.6mm thickness throughout the plywood having open knots and occasional open splits or joints in the core.

Bonding Bonding

- Phenolic resin cross-bonded weather resistant gluing according to EN 314-2 class 3 exterior.

Effect of humidity and moisture

- Wood veneer is a living material and is subject to moisture movement according to surrounding conditions, which affects the flatness of panels. It is important to condition the panels to reach a moisture content near to the equilibrium of their permanent environment.

- Like other wood-based panel products, Birch Plywood is also hygroscopic and its dimensions change in response to a change in humidity. A change of 1% in moisture content typically increases or decreases the length, width and thickness by 1% in dimensions and thickness. It is therefore desired that the edges are sealed with a suitable acrylic paint to prevent and/or control ingress of moisture and humidity and consequent swell in thickness and expansion in dimensions.

- The recommended stocking conditions are 20°C and a RH of air of about 60%

Storage conditions:

- The recommended stocking conditions are 20°C and a RH of air of about 60%.

Applications Applications

- Furniture

- Interior linings

- Shop fittings

- Wooden Homes

- Container floors

- Driving ramps

- Construction scaffolding

- Cold storage cargo holds

- Traffic signs and notices

- Building and construction

- Trade and storage equipment

- Carcass and upholstered furniture

- Silos:

- Packaging, Crates & Boxes,

Availability options: Availability options:

CDX/CCX Plywood is made in a range of thickness from 12mm to 21mm CDX/CCX Plywood is made in a range of thickness from 12mm to 21mm

- The most commonly available dimension is 2440mm x 1220mm.

Preservatives

Plywood is made from natural wood Veneers grown and harvested in Uruguay and is free from any toxic chemicals except resin. As is common knowledge, all wood products are susceptible to insects or termites and/or borers present in different climatic zones in the soil or buildings. It is recommended that the users are applying the coat of suitable chemicals or insecticides on all exposed surfaces of wood in addition to treatment of masonry foundations of the building where the Wood products are required to be use. Fipronil emulsified concentrate at about 3% is one such chemical and effective deterrent against insects and pests or termites in tropical climate zones. However, the application should be in accordance with manufacturers guidelines for effective results. Users own discretion in selection of appropriate chemical and its doses or frequency of such treatment is advised for satisfactory results in the light of experience gained over the period of time. Plywood is made from natural wood Veneers grown and harvested in Uruguay and is free from any toxic chemicals except resin. As is common knowledge, all wood products are susceptible to insects or termites and/or borers present in different climatic zones in the soil or buildings. It is recommended that the users are applying the coat of suitable chemicals or insecticides on all exposed surfaces of wood in addition to treatment of masonry foundations of the building where the Wood products are required to be use. Fipronil emulsified concentrate at about 3% is one such chemical and effective deterrent against insects and pests or termites in tropical climate zones. However, the application should be in accordance with manufacturers guidelines for effective results. Users own discretion in selection of appropriate chemical and its doses or frequency of such treatment is advised for satisfactory results in the light of experience gained over the period of time.

|

|

|