OSB 3 - Oriented Strand Board from Kronospan OSB 3 - Oriented Strand Board from Kronospan

Oriented Strand Board (OSB) produced by Kronospan in Romania (EC) is a performance based engineered, mat-formed panel product made of Spruce, Pine and Beech Wood strands, flakes or wafers and bonded with an exterior-type formaldehyde free PU binder under heat and pressure. High Moisture Resistant MDI/PMDI resin binders are combined with the strands to provide internal strength, rigidity and moisture resistance. Oriented Strand Board (OSB) produced by Kronospan in Romania (EC) is a performance based engineered, mat-formed panel product made of Spruce, Pine and Beech Wood strands, flakes or wafers and bonded with an exterior-type formaldehyde free PU binder under heat and pressure. High Moisture Resistant MDI/PMDI resin binders are combined with the strands to provide internal strength, rigidity and moisture resistance.

OSB 3 meets or exceeds the performance standards of any Moisture resistant plywood and is also cost effective for uses in interior conditions. OSB 3 meets or exceeds the performance standards of any Moisture resistant plywood and is also cost effective for uses in interior conditions.

OSB 3 has excellent moisture tolerance and suitable in both dry and highly humid areas of applications and absolutely free from insects and termite infestations in its natural form even without any preservative treatment. In addition, OSB3 has exceptional dimensional stability and a uniform structure with no knots or core voids without any tendencies to warp, twist, cup or bend. OSB 3 has excellent moisture tolerance and suitable in both dry and highly humid areas of applications and absolutely free from insects and termite infestations in its natural form even without any preservative treatment. In addition, OSB3 has exceptional dimensional stability and a uniform structure with no knots or core voids without any tendencies to warp, twist, cup or bend.

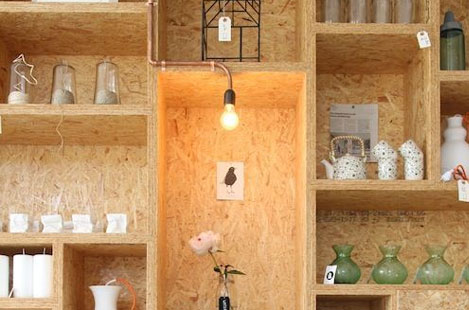

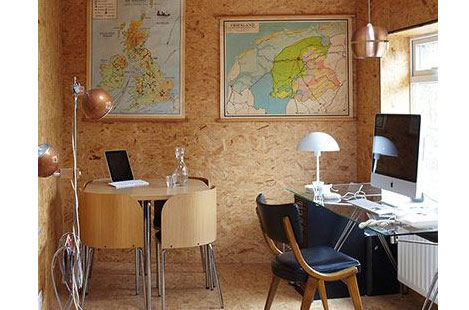

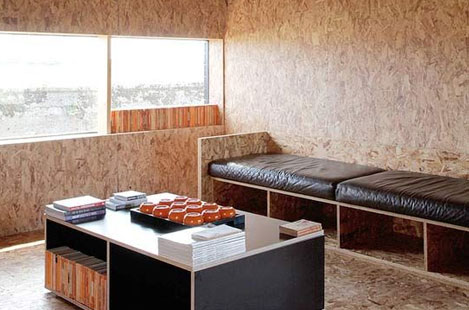

OSB 3 is highly recommended as a structural wood panel and conforms to practically all international standards for applications in Buildings including sheathings and roofing, cabinetries and durable packaging. OSB 3 is highly recommended as a structural wood panel and conforms to practically all international standards for applications in Buildings including sheathings and roofing, cabinetries and durable packaging.

OSB 3 is also compliant California ARB regulations Phase 1 and 2, being exempted. OSB 3 is also compliant California ARB regulations Phase 1 and 2, being exempted.

is environment friendly solution in our times to save tropical hardwood forests from extinction and augment the initiatives of sustainable forestry by using the thinning of the plantations as its constituent wood. is environment friendly solution in our times to save tropical hardwood forests from extinction and augment the initiatives of sustainable forestry by using the thinning of the plantations as its constituent wood.

Standard  OSB OSB

EN 300 as applicable to OSB 3 - Load bearing boards for use in humid conditions.

Key Benefits  OSB OSB

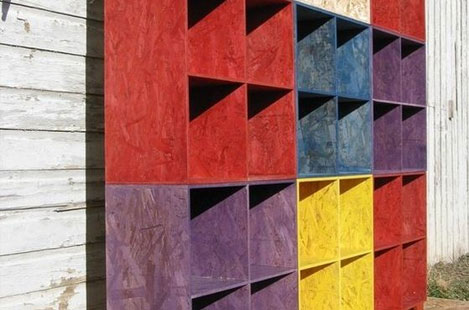

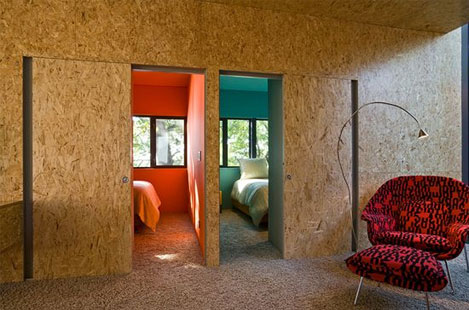

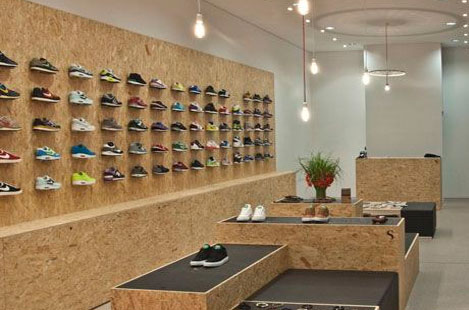

- High performance and natural look

- No Added Formaldehyde (NAF) resin bonded

- Fresh indoor air quality,

- Resistance to temperature variation: through a range of -40°C

to +50°C (-40°F to +122°F), comes in a variety of thicknesses and sizes

What does our promise of Efficiency mean to you

- Products that improve your cost, material and energy efficiency

- Reliable and timely deliveries

- Local knowledge, support and service

- Solutions for every application

- Proven and documented technical data and environmental statements

Properties  OSB OSB

- Dimensionally stable, accurate & stable.

- Strong and light

- Meets EUTR standards,

Bonding  OSB OSB

- Non-formaldehyde synthetic resin MDI/PMDI is used as binder in OSB 3. However, the natural formaldehyde in the veneer strands do emit formaldehyde but such emission is far below the limits set out in EN 13986.

Thermal conductivity

- The thermal conductivity (l) of OSB as determined according to BS EN 12664 Thermal performance of building materials and products. Determination o f thermal resistance by means of guarded hot plate and heat flow meter methods. Dry and moist products of medium and low thermal resistance5 is 0.13 W/m.K for

a mean density of 650 kg/m3 as set out in BS EN 13986.

Availability options:

Panel sizes commonly available is 2440mm x 1220mm in thickness 12mm & 18mm. Other dimensions can also be arranged with prior arrangement.

Effect of humidity and moisture

- Wood Fibers is a living material and is subject to moisture movement according to surrounding conditions, which affects the flatness and thickness swell of panels. .It is important to condition the panels to reach a moisture content near to the equilibrium of their permanent environment. The recommended stocking conditions are 20°C and a RH of air of about 60%.

- Wetting of OSB should be avoided. OSB3 is not waterproof; the term ‘moisture resistant’ applies to the adhesive binder which will not break down in the presence of moisture (within BS EN 300 limits).

- Like other wood-based panel products, OSB is hygroscopic and its dimensions change in response to a change in humidity. A change of 1% in moisture content typically increases or decreases the length, width and

thickness of the OSB by 1% in dimensions and thickness.

It must not be exposed to wet or high humidity conditions!

Storage conditions:

- The recommended stocking conditions are 20°C and a RH of air of about 60%. The boards should be stored in their intended installation area for a minimum of 48 hours to acclimatise to the surrounding temperature and humidity. Check for any damages before fitting.

Precautions and General Advice

- Wetting of OSB must be avoided. OSB3 is not waterproof; the term ‘moisture resistant’ applies to the adhesive binder which will not break down in the presence of moisture (within BS EN 300 limits).

- All common woodworking tools can be used successfully with Kronospan OSB 3. As a general rule, cutting speeds should be lower than for conventional wood. Carbide or diamond tipped blades and cutters are recommended because of their longer cutting life.

- Boards with straight edges need 2-3 mm dilatation gap at the edges of the boards for possible moisture expansion, depending upon the assessment of risk.

by the users.

- Corrosion resistant fasteners should be used where OSB is part of a load bearing structure. Structural fastening systems are only

permitted if their use has been approved by the manufacturer.

- Guidance on the use of OSB in load-bearing applications is given in DD CEN/TS 12872.

- OSB 3 boards must be free from direct exposure to weather conditions, sun light and rains to prevent from weathering and decay.

- Physical wetting of all grades of OSB should be avoided. When wet, OSB will increase appreciably in thickness and start the weathering and decay process.

- OSB will not normally be attacked by wood-boring insects common in temperate climates as these are susceptible to fungal attack under prolonged wet conditions.

General Properties of OSB

PROPERTY |

TEST METHOD |

UNIT |

VALUE |

| Tolerances on nominal dimensions |

Length & Width |

EN 324-1 |

mm |

± 3.0 |

| Thickness 1,2 |

EN 324-1 |

mm |

± 0.3 (sanded), ± 0.8 un-sanded |

| Edge straightness tolerance 1 |

EN 324-2 |

mm/m |

1.5 |

| Squareness tolerance 1 |

EN 324-2 |

mm/m |

2 |

| Moisture content |

EN 322 |

% |

2 - 12% |

| Tolerance on the mean density within a board |

EN 323 |

% |

± 15 |

| Formaldehyde release according to EN 13986 3 |

EN 120 |

mg/100g |

E1 |

≤8mg/100g |

1These values are characterised in the material corresponding to a relative humidity of 65% and temperature of 20° C

2These values are characterised between and within boards

3Perforator values are related to boards with moisture of 6,5%. In the case of boards with different moisture content the perforator value is recalculated.

Properties for load bearing boards for the use in humid conditions (type OSB 3):

PROPERTY |

TEST METHOD |

UNIT |

NOMINAL THICKNESS, mm |

| 6 to 10 |

>10 to <18 |

18 to 25 |

>25 to 32 |

| Bending Strength - major axis |

EN 310 |

N/mm2 |

22 |

20 |

18 |

16 |

| Bending Strength - minor axis |

EN 310 |

N/mm2 |

11 |

10 |

9 |

8 |

| Bending strength after cyclic test - major axis1, 2 |

EN 321 |

N/mm2 |

9 |

8 |

7 |

6 |

| MOE in bending - major axis |

EN 310 |

N/mm2 |

3500 |

| MOE in bending - minor axis |

EN 310 |

N/mm2 |

1400 |

| Internal Bond |

EN 319 |

N/mm2 |

0.34 |

0.32 |

0.30 |

0.29 |

after cyclic test 1 |

EN 321 |

N/mm2 |

0.18 |

0.15 |

0.13 |

0.10 |

after boil test 3; |

EN 321 |

N/mm2 |

0.15 |

0.13 |

0.12 |

0.6 |

| Swelling in thickness - 24h |

EN 322 |

% |

15 |

1Option 1 for moisture resistance requirement

2For the calculation of bending strength after cyclic test, the thickness taken to account is the thickness measured after the cyclic test

3Option 2 for moisture resistance requirement

Certifications:

OSB is also available under chain of custody programs on prior arrangement. Please check availability. OSB is also available under chain of custody programs on prior arrangement. Please check availability.

OSB is also certified for conformity with California ARB regulation No. 93120.2 as applicable to Phase 2. Please check availability. OSB is also certified for conformity with California ARB regulation No. 93120.2 as applicable to Phase 2. Please check availability.

|