high density MDF is German DIN EN-16516:2018-01 and REACh compliant high density MDF is German DIN EN-16516:2018-01 and REACh compliant

Germany announced DIN EN-16516:2018-01 as the new reference method for formaldehyde emission from wood-based materials, effective January 1, 2020. According to German law, starting from 1 January 2020, wood-based panels and products exported to Germany must comply with the limit of 0.1 ppm obtained with the test method specified in the standard EN 16516. The changes in the new reference method EN-16516:2018-01 are related to air change (it is less in comparison with the current test method EN 717-1) and to the load test that requires an increased test load. However, the method described by the EN 717-1 standard can still be used provided that in this case the resulting emission value is multiplied by 2, halving the emission requirement necessary to comply with the German regulation. . That means limit value 0,05 ppm when using EN 717-1 method whereas United States CARB and EPA TSCA Title VI restricts formaldehyde emissions for MDF to 0.11 ppm (> 8 mm) or 0.13 ppm (≤ 8 mm) depending on the board thickness.

REACh compliant Pinepanels MDF

Registration - Evaluation - Authorisation of Chemicals

In the EU, the chemicals directive REACh has been binding for all EU member states as of 1st June 2007. The REACh system is based on the principle of own responsibility of the industry. Within the region of validity, and based on the ”no data, no market” principle, only those chemical materials may be brought to the market that has previously been registered. The European Chemicals Agency (ECHA) issues a so-called “candidate list” naming the “hazardous substances”. Per the REACh directive, each supplier must identify the listed substances in their paperwork as soon as they take up a weight of more than 0.1 % of the overall product.

Eximcorp affirms that all its panel products comply with the requirements of REACh directive in its latest version.

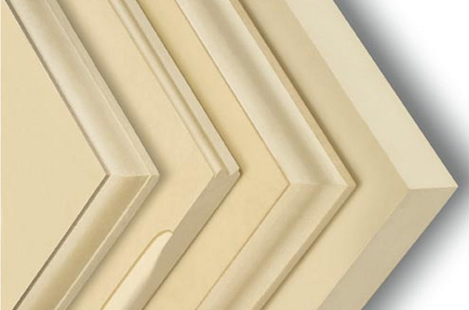

High Density MDF is a specialty, application driven High Density MDF, engineered to meet the challenges in design and performance. Its constituent wood fibre is Pine grown in the native plantations in New Zealand. The wood used in the manufacture is free from pollution by previous use or presence of foreign substances that saves on cost of tools and helps smooth production flow at ends user’s factories. High Density MDF is a specialty, application driven High Density MDF, engineered to meet the challenges in design and performance. Its constituent wood fibre is Pine grown in the native plantations in New Zealand. The wood used in the manufacture is free from pollution by previous use or presence of foreign substances that saves on cost of tools and helps smooth production flow at ends user’s factories.

MDF Panels are brightest in the market in color and appearance. This ensures fewer color application to achieve desired finish. MDF Panels are brightest in the market in color and appearance. This ensures fewer color application to achieve desired finish.

It is unrivalled in its quality and performance  High Density MDF is the hallmark of consumer’s confidence in the MDF market to-day. High Density MDF is the hallmark of consumer’s confidence in the MDF market to-day.

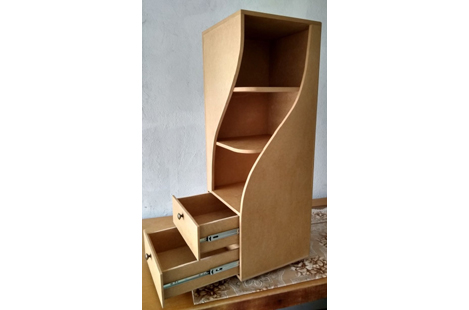

While  High Density MDF has literally innumerable interior applications in the cabinet-making, shop fitting, furniture and building industries, Hand crafted souvenirs etc, its excellent machining and finishing attributes combined with good working properties and its availability in a wide range of sheet thicknesses and sizes makes it a first choice MDF panel. High Density MDF has literally innumerable interior applications in the cabinet-making, shop fitting, furniture and building industries, Hand crafted souvenirs etc, its excellent machining and finishing attributes combined with good working properties and its availability in a wide range of sheet thicknesses and sizes makes it a first choice MDF panel.

It must not be exposed to wet or high humidity conditions!

Value added variants such as Exterior and High Performance High Density MDF is being extended into powder coating application, shop fitting and display, interior fitments as well as components within numerous other MDF products. The term ‘High Performance MDF’ refers to High Density MDF specially engineered to withstand specific application requirements of the MDF panel.

Key Benefits  MDF MDF

- Low formaldehyde emissions, meets or exceeds the German DIN-EN-16516:2018-01

- Compliant REACh Standard

- Compliant US EPA Regulation RIN:2070-AJ44, CFR:40 CFR Part 770

- Compliant California ARB regulation No 93120.2 on Phase 2,

- Fresh indoor air quality, free from toxic VOCs

- Resistance to temperature variation: through a range of-40°C to +50°C (-40°F to +122°F), comes in a variety of thicknesses and sizes

- Meets EUTR standards upon request,

What does our promise of Efficiency mean to you

- Products that improve your cost, material and energy efficiency

- Reliable and timely deliveries

- Local knowledge, support and service

- Solutions for every application

- Proven and documented technical data and environmental statements

Properties  MDF MDF

- Sanded surfaces,

- Dimensionally stable, accurate & stable.

- Strong and light

- CNC Routable and can be machined,

Fibers

- 100% natural plantation grown wood fibers from Pine wood.

Bonding  MDF MDF

- UF and/or MUF low emitting resin.

Effect of humidity and moisture

- Wood Fibres is a living material and is subject to moisture movement according to surrounding conditions, which affects the flatness and thickness swell of panels. .It is important to condition the panels to reach moisture content near to the equilibrium of their permanent environment. The recommended stocking conditions are 20°C and a RH of air of about 60%.

Storage conditions:

- The recommended stocking conditions are 20°C and a RH of air of about 60%.

Certifications:

of high density MDF is also certified for conformity with German DIN-EN-16516:2018-01 as also California ARB regulation No. 93120.2 as required.. Please check availability. of high density MDF is also certified for conformity with German DIN-EN-16516:2018-01 as also California ARB regulation No. 93120.2 as required.. Please check availability.

|