|

|

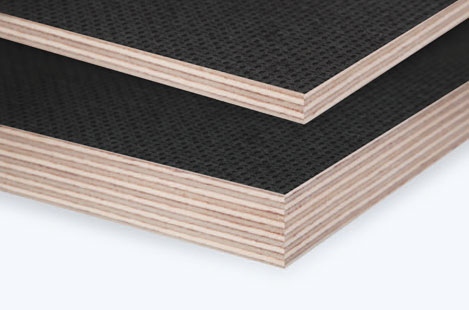

- Trucks & Bus Flooring Plywood - Trucks & Bus Flooring Plywood

An ultimate in performance and durability

is a special film faced plywood coated with wear resistant phenolic film This plywood has a mesh working surface. Its edges are protected with water-dispersible acrylic paint. is a special film faced plywood coated with wear resistant phenolic film This plywood has a mesh working surface. Its edges are protected with water-dispersible acrylic paint.

Titan plywood is specially designed for applications where high wear resistance and anti-slip properties are required: vehicle floors, industrial flooring, load bearing platforms, storage racks.

Certifications

- Certified products are also available under the chain of custody programs on prior arrangement

What does our promise of Efficiency mean to you

- Products that improve your cost, material and energy efficiency

- Reliable and timely deliveries

- Local knowledge, support and service

- Solutions for every application

- Proven and documented technical data and environmental statements

Properties Properties

- Anti-Skid flooring panel

- Wear resistant

- Slip resistant

End-uses End-uses

- Trailers

- Trucks

- Bus floors

- Railway wagons

- Warehouses

- Loading platforms

- Scaffolding

Bonding Bonding

- Titan is bonded with Phenolic resin cross-bonded weather resistant gluing according to EN 314-2/class 3.

Effect of humidity and moisture

- Wood veneer is a living material and is subject to moisture movement according to surrounding conditions, which affects the flatness of panels. It is important to condition the panels to reach a moisture content near to the equilibrium of their permanent environment.

- Like other wood-based panel products, Birch Plywood is also hygroscopic and its dimensions change in response to a change in humidity. A change of 1% in moisture content typically increases or decreases the length, width and thickness by 1% in dimensions and thickness. It is therefore desired that the edges are sealed with a suitable acrylic paint to prevent and/or control ingress of moisture and humidity and consequent swell in thickness and expansion in dimensions.

- The recommended stocking conditions are 20°C and a RH of air of about 60%.

Surface

- Face: Phenolic resin coating with wire mesh pattern, dark brown or black.

Reverse: Phenolic moisture barrier. Available either smooth or imprinted.

Edge protection: Acryl-based paint

Coating Weight: 120 g or 220 g/m2

What does our promise of Efficiency mean to you

- Products that improve your cost, material and energy efficiency

- Reliable and timely deliveries

- Local knowledge, support and service

- Solutions for every application

- Proven and documented technical data and environmental statements

Panel sizes Panel sizes

Standard dimensions:

- 1220 x 2440 mm

- 1250 x 2500 mm

- 1500 x 3000 mm

- 1525 x 3050 mm

Squareness tolerance:

±1 mm / 1000 mm

Preservatives

Plywood is made from natural Birch wood Veneers grown and harvested in Russia and is free from any toxic chemicals except resin. As is common knowledge, all wood products are susceptible to insects or termites and/or borers present in different climatic zones in the soil or buildings. It is recommended that the users are applying the coat of suitable chemicals or insecticides on all exposed surfaces of wood in addition to treatment of masonry foundations of the building where the Wood products are required to be use. Fipronil emulsified concentrate at about 3% is one such chemical and effective deterrent against insects and pests or termites in tropical climate zones. However, the application should be in accordance with manufacturers guidelines for effective results. Users own discretion in selection of appropriate chemical and its doses or frequency of such treatment is advised for satisfactory results in the light of experience gained over the period of time. Plywood is made from natural Birch wood Veneers grown and harvested in Russia and is free from any toxic chemicals except resin. As is common knowledge, all wood products are susceptible to insects or termites and/or borers present in different climatic zones in the soil or buildings. It is recommended that the users are applying the coat of suitable chemicals or insecticides on all exposed surfaces of wood in addition to treatment of masonry foundations of the building where the Wood products are required to be use. Fipronil emulsified concentrate at about 3% is one such chemical and effective deterrent against insects and pests or termites in tropical climate zones. However, the application should be in accordance with manufacturers guidelines for effective results. Users own discretion in selection of appropriate chemical and its doses or frequency of such treatment is advised for satisfactory results in the light of experience gained over the period of time.

|

|

Related Documents

Related knowledge documents :

US Lacey Act - Declaration Form US Lacey Act - Declaration Form

FAQ- The US Lacey Act FAQ- The US Lacey Act

EPA Wood Composite FAQ EPA Wood Composite FAQ

US EPA formaldehyde-emission-standard US EPA formaldehyde-emission-standard

EPA-EPA-950-F-17-001 EPA-EPA-950-F-17-001

|