CARB & EPA compliant Pine High Density Fiber Board

High Density Fiber Board is compliant Phase 2 emission limits of the California Air Resources Board Regulation 93120.2 and US EPA regulation No: RIN:2070-AJ44, CFR:40 CFR Part 770 as certified by approved third party certifier. The California ARB and US EPA compliant HDF panels are imported under chain of custody procedure and every single HDF panel traded is traceable to its TPC certified manufacturing facility. High Density Fiber Board is compliant Phase 2 emission limits of the California Air Resources Board Regulation 93120.2 and US EPA regulation No: RIN:2070-AJ44, CFR:40 CFR Part 770 as certified by approved third party certifier. The California ARB and US EPA compliant HDF panels are imported under chain of custody procedure and every single HDF panel traded is traceable to its TPC certified manufacturing facility.

High Density Fiber Board is a specialty, application driven Fiber Board, engineered to meet the challenges in design and performance. Its constituent wood fiber is Pine grown in the native plantations in New Zealand & Americas. The wood used in the manufacture is free from pollution by previous use or presence of foreign substances that saves on cost of tools and helps smooth production flow at ends user’s factories. High Density Fiber Board is a specialty, application driven Fiber Board, engineered to meet the challenges in design and performance. Its constituent wood fiber is Pine grown in the native plantations in New Zealand & Americas. The wood used in the manufacture is free from pollution by previous use or presence of foreign substances that saves on cost of tools and helps smooth production flow at ends user’s factories.

Constituent Pine being softwood yields light weight fibers, more or less uniform in its density which ensures a significantly higher compression of fiber and resin in the same density of HDF Panel made from hardwood like Rubber wood or Eucalyptus or Re-cycled wood fibers. Usage of low formaldehyde emission UF or MUF resin makes it an environment friendly and safe Fiber Board product for your home and office.

It is unrivalled in its quality and performance  High Density Fiber Board is the hallmark of consumer’s confidence in the market to-day. High Density Fiber Board is the hallmark of consumer’s confidence in the market to-day.

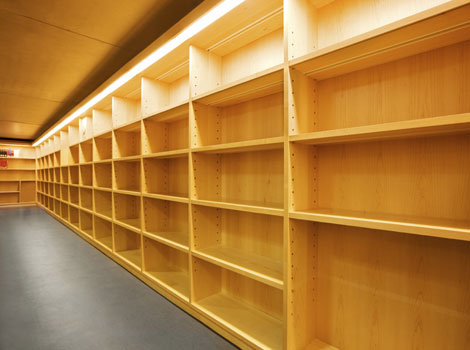

While  High Density Fiber Board has literally innumerable interior applications in the cabinet-making, shop fitting, furniture and building industries, Hand crafted souvenirs etc, its excellent machining and finishing attributes combined with good working properties and its availability in a wide range of sheet thicknesses and sizes makes it a first choice HDF panel. High Density Fiber Board has literally innumerable interior applications in the cabinet-making, shop fitting, furniture and building industries, Hand crafted souvenirs etc, its excellent machining and finishing attributes combined with good working properties and its availability in a wide range of sheet thicknesses and sizes makes it a first choice HDF panel.

It must not be exposed to wet or high humidity conditions!

The exceptionally large size of the Panels allows optimum recovery and saves on wastages considerably. Southern Yellow Pine having long fibers is your guarantee for highest MOE & MOR properties in the panel and thus especially recommended for applications having static load.

It is a value added variant of High Density Fiber Board and has exceptional high performance characteristics and is considered to be most suitable panel for powder coating application, shop fitting and display, interior fitments as well as components within numerous other products.

Key Benefits  MDF MDF

- High performance and Seamless finish

- Durable, sound and hard sanded surface

- Routable, machinable

- Low formaldehyde emissions, meets or exceeds the European E1 and California ARB regulation No 93120.2 on Phase 2 &EPA Regulation No:RIN-2070-AJ44, CFR:40 CFR Part 770

- Fresh indoor air quality, free from toxic VOCs

- Resistance to temperature variation: through a range of -40°C

to +50°C (-40°F to +122°F), comes in a variety of thicknesses and sizes

What does our promise of Efficiency mean to you

- Products that improve your cost, material and energy efficiency

- Reliable and timely deliveries

- Local knowledge, support and service

- Solutions for every application

- Proven and documented technical data and environmental statements

Properties  MDF MDF

- Sanded surfaces,

- Dimensionally stable, accurate & stable.

- Strong and light

- CNC Routable and can be machined,

- Meets EUTR standards,

- Meets European E1 formaldehyde emission requirements (EN 622-1:2003) and also California ARB regulation P2 and EPA regulation on wood composites.

Fibers  MDF MDF

- 100% natural plantation grown wood fibers from Soft wood.

Bonding  MDF MDF

- UF and/or MUF low emitting resin.

Effect of humidity and moisture

- Wood Fibers is a living material and is subject to moisture movement according to surrounding conditions, which affects the flatness and thickness swell of panels. .It is important to condition the panels to reach a moisture content near to the equilibrium of their permanent environment. The recommended stocking conditions are 20°C and a RH of air of about 60%.

Storage conditions:

The recommended stocking conditions are 20°C and a RH of air of about 60%.

Certifications:

of high density MDF is also available under chain of custody programs of PEFC on prior arrangement. Please check availability. of high density MDF is also available under chain of custody programs of PEFC on prior arrangement. Please check availability.

of high density MDF is also certified for conformity with California ARB regulation No. 93120.2 as applicable to Phase 2. Please check availability. of high density MDF is also certified for conformity with California ARB regulation No. 93120.2 as applicable to Phase 2. Please check availability.

Availability options:

2460mm x 2076mm x 6.4mm

2620mm x 1455mm x 7.3mm

2460mm x 2076mm x 7.6mm

2460mm x 2076mm x 9.4mm

2440mm x 2133mm x 11.4mm

2440mm x 2133mm x 11.6mm

Technical Specification

| Properties |

Values |

| Moisture Content |

Max: 9% and variable on atmospheric humidity |

| Density range |

800 - 1000 kg m3 |

| Thickness tolerance |

|

| Between Panels |

+/- 0.125mm |

| Within Panels |

+/- 0.125mm |

| Modulus of rupture |

28.9 N/mm2 |

| Modulus of elasticity |

2900 - 3300 N/mm2 |

| Internal bond |

0.90 N/mm2 |

| Linear expansion |

< 0.33% |

| Screw Holding |

|

| Face |

1800 N |

| Core |

1000 N |

| Formaldehyde emissions |

< 0.1 ppm |

| |

Compliant CARB PII TPC 1 |

|

|

|

![]() is the registered trade mark of Eximcorp India Pvt Ltd. 25 RN Mookherjee Road, Kolkata 700001 (india)

is the registered trade mark of Eximcorp India Pvt Ltd. 25 RN Mookherjee Road, Kolkata 700001 (india)